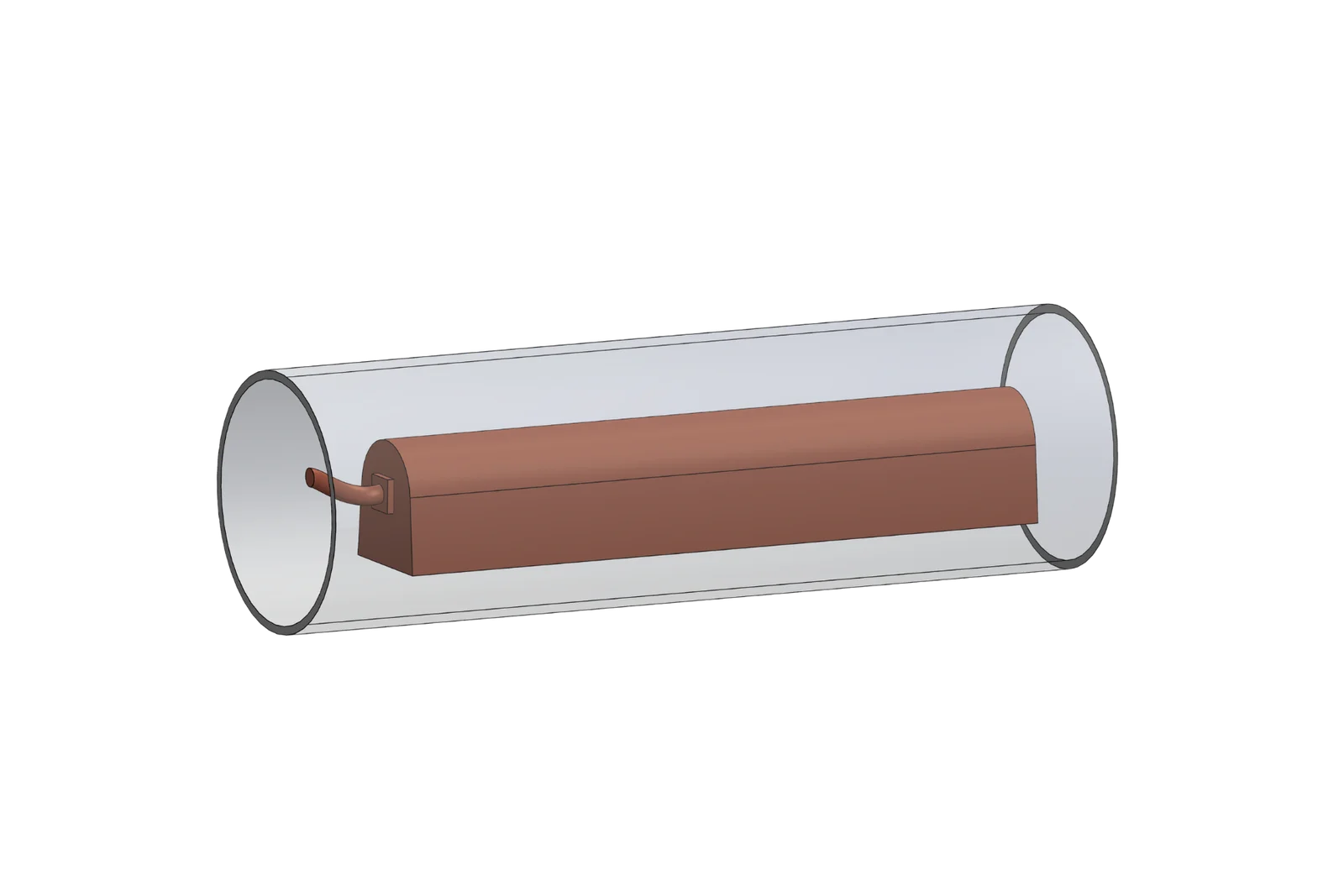

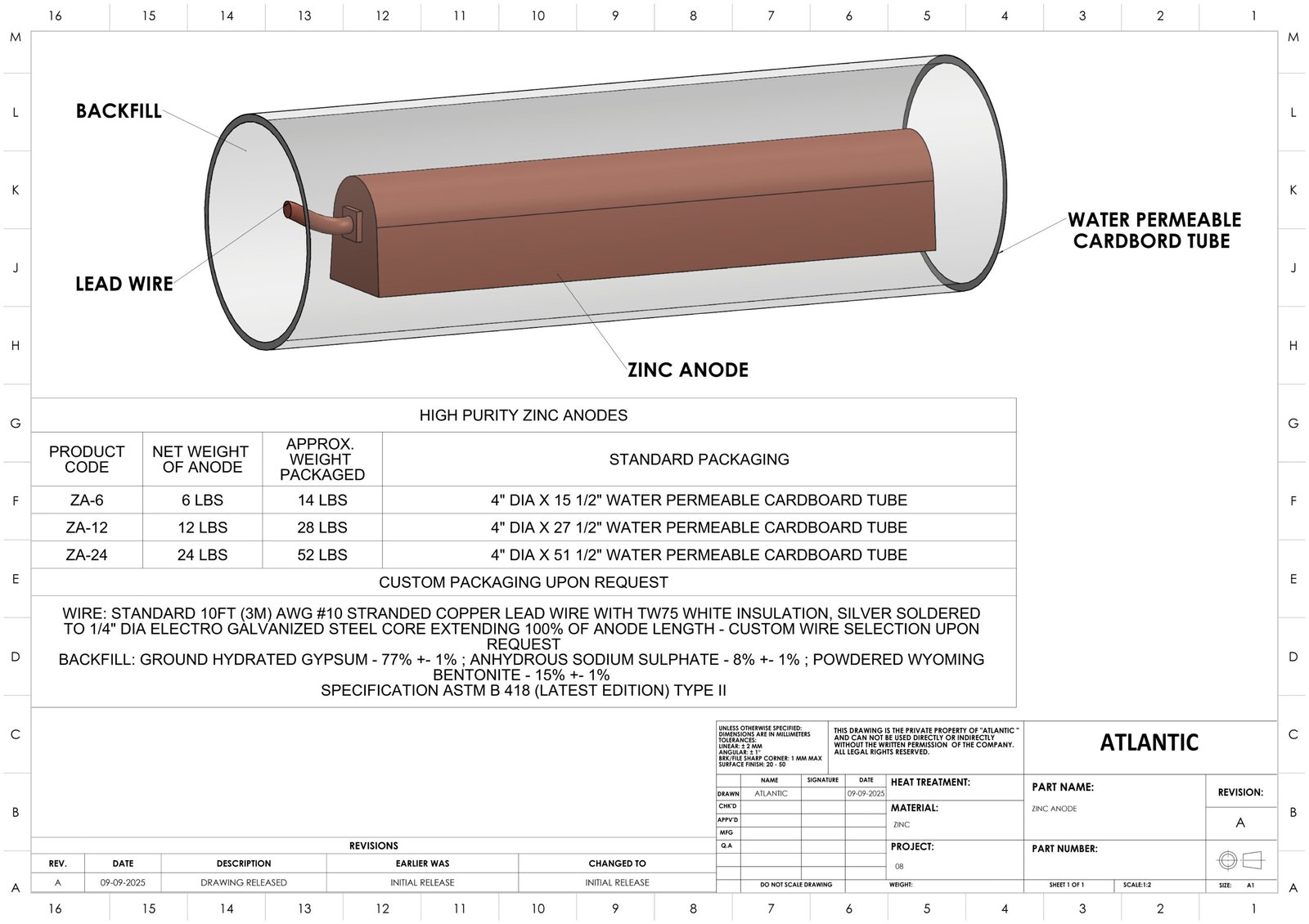

Zinc Anodes are designed to provide highly effective sacrificial corrosion protection for steel structures in cathodic protection systems. With stable electro chemical performance and controlled driving potential, they ensure long-term protection in soil, freshwater, and other low-resistivity environments.

| Item |

Zinc Anodes |

| Product Description |

High Purity Zinc Anodes |

| Material |

Zinc |

| Coating |

Uncoated |

| Standard / Classifications |

ASTM G97-97 |

Installation Steps

- Select the appropriate zinc anode size and type based on the specific marine or underground application.

- Clean the metal surface of the structure to ensure proper electrical connection.

- Position the zinc anode in direct contact with water or soil where corrosion protection is required.

- Attach the anode securely using approved clamps, welds, or bolted connections depending on the application.

- Ensure the anode has a solid electrical connection to the structure by checking continuity with a meter.

- For underground use, place the anode in a moist, conductive environment to maximize performance.

- Verify proper installation by measuring the protection potential after the anode is fixed in place.

Common Applications

- Where the sulphur present in the water.

- where there is hard water or little intrusion of salt water

- There is need of slow corroding anode in aggressive water condition.

- Marine Vessels: Used to protect ship hulls, rudders, and propellers from galvanic corrosion in

seawater

- Offshore Structures: Ideal for platforms, piers, and submerged components exposed to saltwater

- Underground Pipelines: Provides cathodic protection in high-conductivity soils

- Storage Tanks: Protects the internal and external surfaces of steel tanks in marine or coastal

environments

- Heat Exchangers & Condensers: Prevents corrosion in cooling water systems and marine HVAC

units