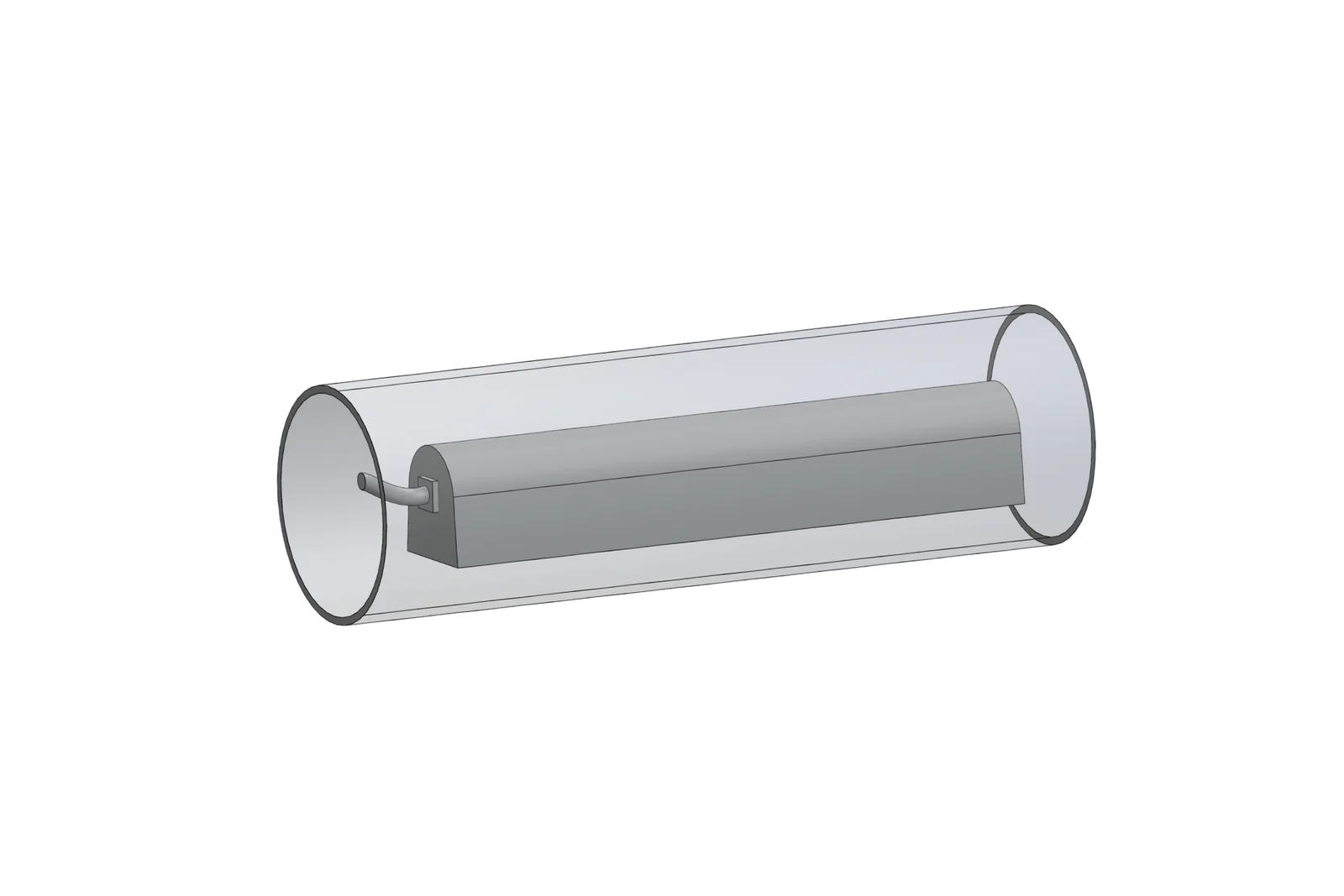

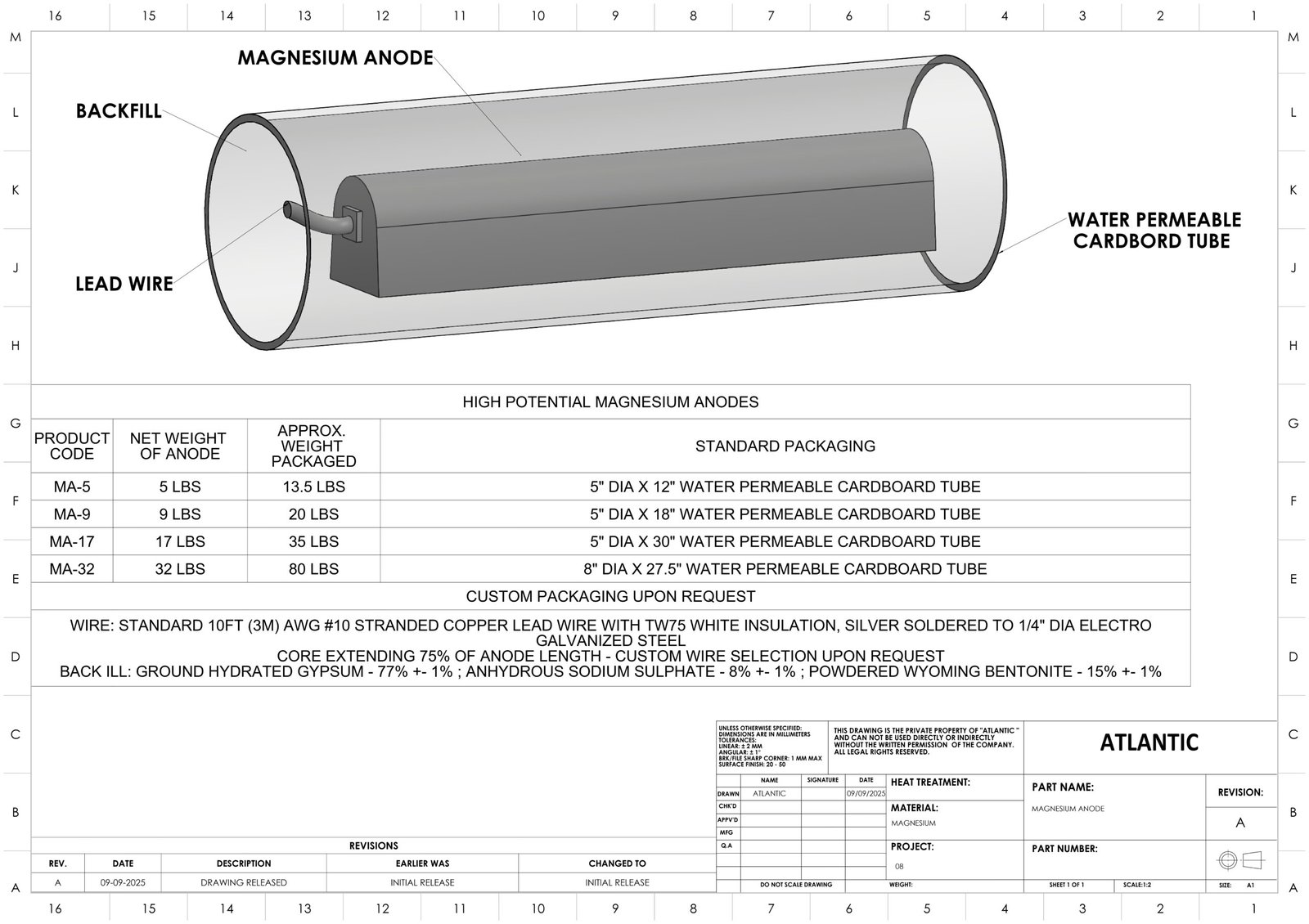

Magnesium Anodes are engineered to deliver highly efficient sacrificial corrosion protection for steel structures used in cathodic protection systems. Known for their high driving potential, they provide reliable and long-lasting protection in low-resistivity soils, freshwater, and underground environments.

| Item |

Magnesium Anodes |

| Product Description |

High Potential Magnesium Anodes |

| Material |

Magnesium |

| Coating |

Uncoated |

| Standard / Classifications |

ASTM B843 (latest edition) |

Installation Steps

- Determine the required anode size and type based on soil resistivity and structure protection needs.

- Excavate a pit or trench at the specified distance from the structure to be protected.

- Prepare a backfill mixture (typically gypsum, bentonite, and sodium sulfate) if using packaged anodes.

- Place the magnesium anode in the trench or pit, ensuring the lead wire is positioned toward the structure.

- Connect the anode lead wire to the structure using approved welding or mechanical connection methods.

- Verify electrical continuity and measure the open-circuit potential before backfilling.

- Backfill carefully with native soil or prepared backfill, compacting gently to ensure good soil contact.

- Test the system after installation to confirm proper cathodic protection performance.

Common Applications

- The magnesium anodes are implied where there is the soft water or moderate hard water.

- When there is no sulphur present in the water.

- When there is need of maximum corrosion protection in standard residential setups.

- Water Pipelines: Provides cathodic protection for underground steel and ductile iron pipelines

- Storage Tanks: Ideal for protecting buried and above-ground steel storage tanks from corrosion

- Oil & Gas Industry: Used to safeguard steel pipelines, fittings, and buried infrastructure

- Residential & Commercial Plumbing: Prevents corrosion in water heaters and metal plumbing

systems

- Marine Structures: Helps protect docks, piers, and submerged metal components in

low-conductivity waters