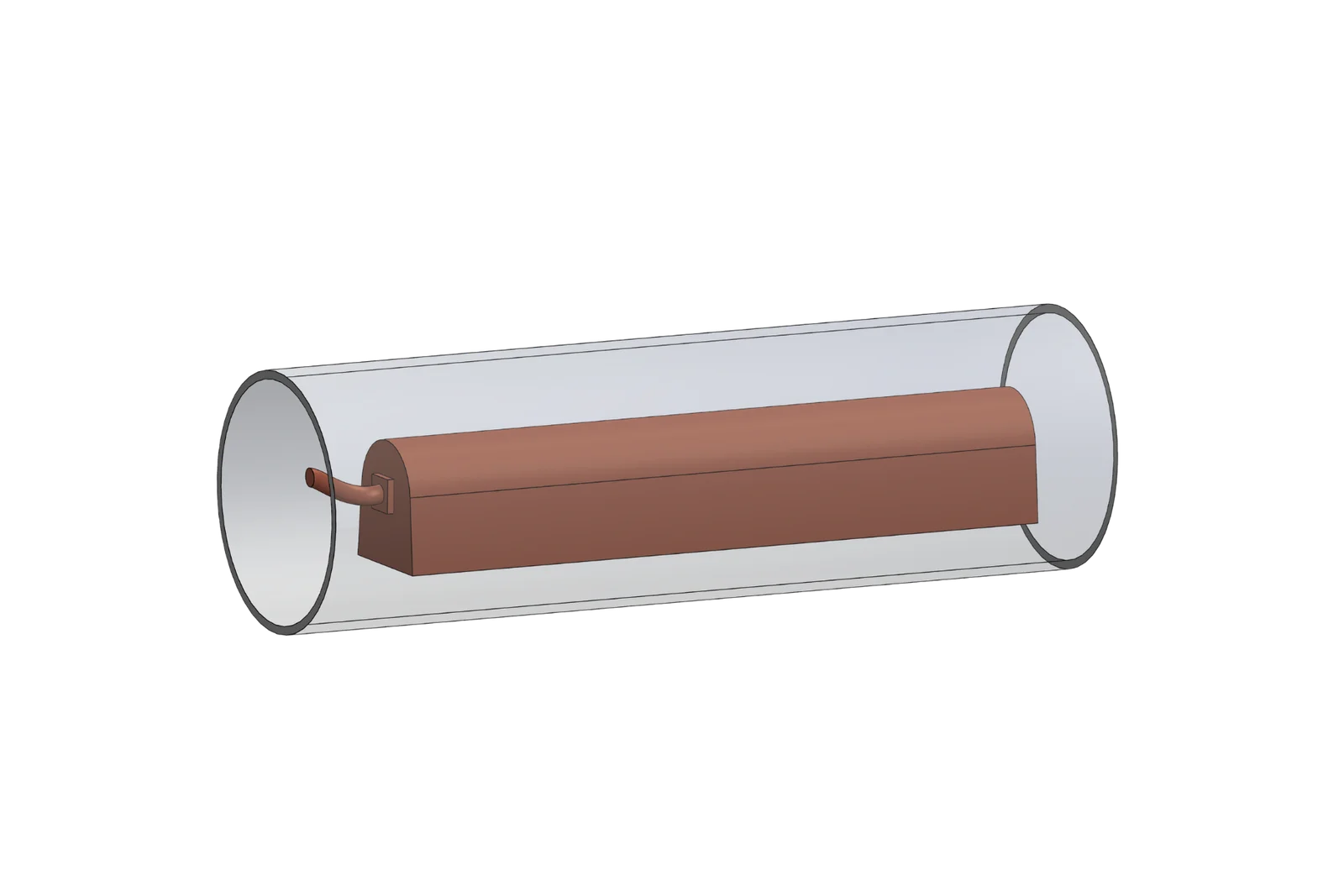

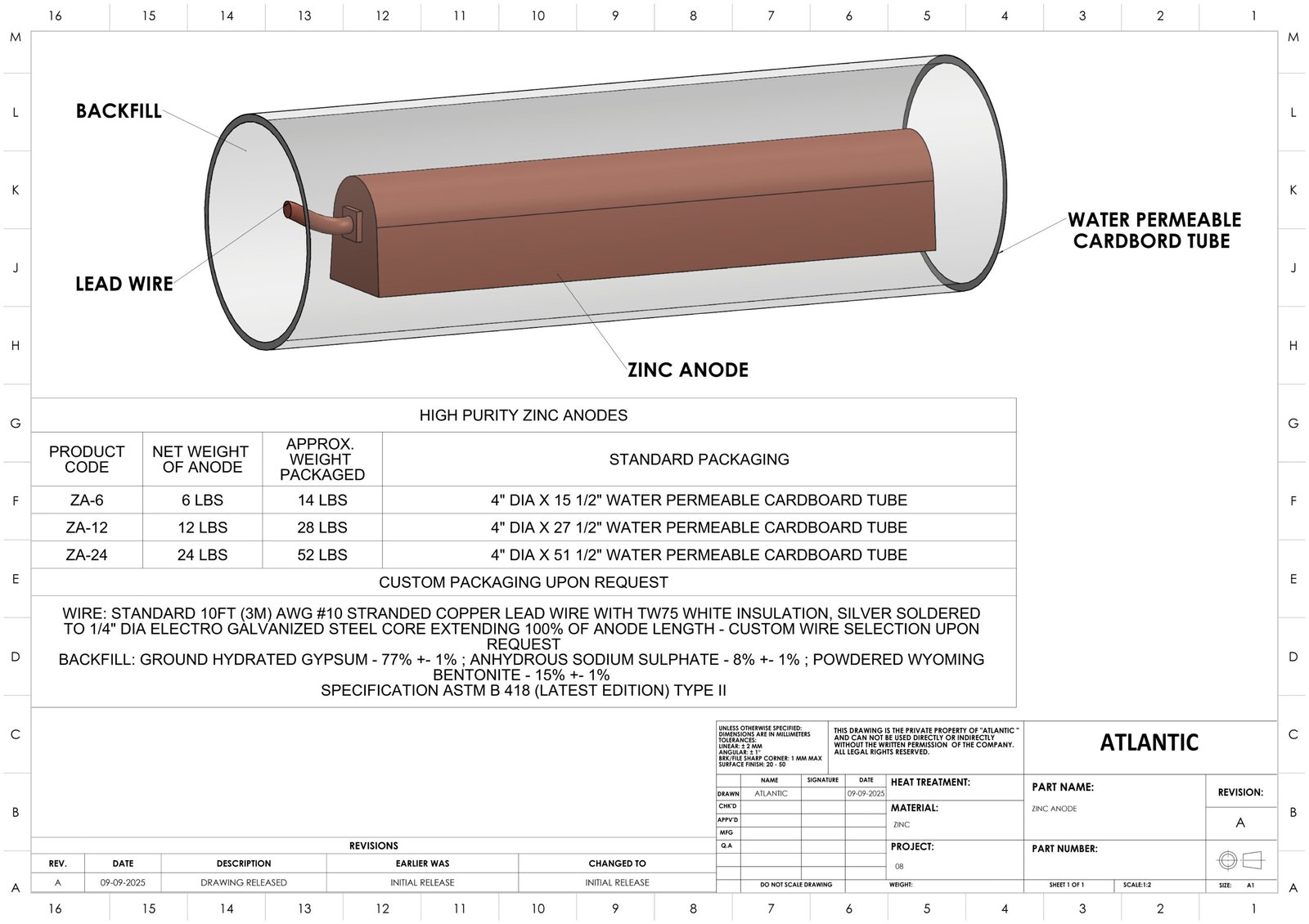

The Zinc Anodes is engineered for highly effective sacrificial anodes used in cathodic protection systems to safeguard steel structures, pipelines, storage tanks, and water heaters from corrosion. Known for their superior driving potential, they provide reliable protection in soil, freshwater, and other low-resistivity environments. Manufactured from high-purity zinc, these anodes ensure consistent performance, long service life, and cost-effective protection. They are available in standard and high-potential grades to meet diverse industrial applications. Easy to install and maintain, zinc anodes are an environmentally friendly and dependable solution for controlling corrosion and extending the lifespan of buried or submerged metal assets.

| Item |

Zinc Anodes |

| Product Description |

High Purity Zinc Anodes |

| Material |

Zinc |

| Coating |

Uncoated |

| Standard / Classifications |

ASTM G97-97 |

Installation Steps

- Select the appropriate zinc anode size and type based on the specific marine or underground application.

- Clean the metal surface of the structure to ensure proper electrical connection.

- Position the zinc anode in direct contact with water or soil where corrosion protection is required.

- Attach the anode securely using approved clamps, welds, or bolted connections depending on the application.

- Ensure the anode has a solid electrical connection to the structure by checking continuity with a meter.

- For underground use, place the anode in a moist, conductive environment to maximize performance.

- Verify proper installation by measuring the protection potential after the anode is fixed in place.

Common Applications

- Marine Vessels: Used to protect ship hulls, rudders, and propellers from galvanic corrosion in seawater

- Offshore Structures: Ideal for platforms, piers, and submerged components exposed to saltwater

- Underground Pipelines: Provides cathodic protection in high-conductivity soils

- Storage Tanks: Protects the internal and external surfaces of steel tanks in marine or coastal environments

- Heat Exchangers & Condensers: Prevents corrosion in cooling water systems and marine HVAC units